Uncategorized

Gun CNC: Revolutionizing Firearm Manufacturing

If you’re interested in gun CNC machining, you’re looking at a transformative technology that has changed the way firearms are manufactured. This guide will cover what CNC machining is, its applications in the Ghost Gun for Sale industry, benefits, challenges, and important safety considerations.

What is CNC Machining?

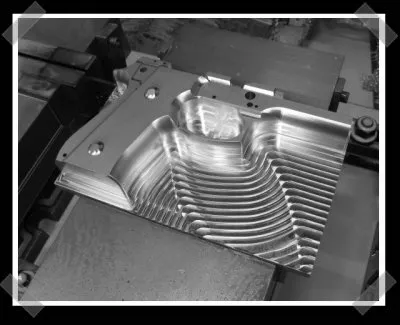

CNC (Computer Numerical Control) machining is a process that uses computer-controlled machines to produce parts from various materials. Using CAD (Computer-Aided Design) software, manufacturers create detailed designs that are converted into machine code, guiding CNC machines to cut, mill, or shape materials with high precision.

Key Features of CNC Machining

- Precision: CNC machines offer exceptional accuracy, crucial for firearm components that require tight tolerances.

- Automation: Once programmed, CNC machines operate autonomously, improving efficiency and reducing labor costs.

- Versatility: CNC technology can work with a wide range of materials, including metals, plastics, and composites.

Applications of CNC Machining in Firearms

1. Manufacturing Gun Parts

CNC machining is widely used to produce various firearm components, including:

- Receivers: The lower receiver houses the trigger mechanism and controls.

- Barrels: Precision machining ensures accuracy and reliability in barrel manufacturing.

- Slides and Frames: CNC technology allows for intricate designs in handgun components.

2. Customization

Gun enthusiasts can use CNC machining to create custom parts tailored to specific needs or preferences, including personalized grips, stocks, and accessories.

3. Prototyping

CNC machining enables rapid prototyping of new firearm designs, allowing manufacturers to test and refine products quickly before mass production.

Benefits of CNC Machining in Firearm Manufacturing

1. Enhanced Precision

CNC machines provide superior accuracy compared to traditional machining methods, critical for reliable firearm performance.

2. Increased Efficiency

The automation of CNC machines reduces production times and labor costs, enabling the swift production of large quantities of parts.

3. Design Flexibility

Designs can be easily modified in CAD software, allowing for quick adjustments in the manufacturing process.

Challenges and Considerations

1. Initial Investment

CNC machines can be costly to purchase and maintain, which may deter small manufacturers or hobbyists.

2. Technical Expertise

Operating CNC machines requires specialized knowledge in machining and programming, Ghost AR Lower necessitating additional training.

3. Regulatory Compliance

Firearm manufacturers must adhere to regulations regarding the production and sale of firearms, including those related to CNC machined parts. Understanding these regulations is essential for legal compliance.

Safety Considerations

When using CNC machinery for firearm manufacturing, prioritize safety:

- Training: Ensure operators are adequately trained in CNC machining and safety protocols.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses and hearing protection.

- Regular Maintenance: Maintain CNC machines to prevent accidents and ensure consistent performance.

Conclusion

Gun CNC machining has revolutionized the firearms industry, offering enhanced precision, efficiency, and customization opportunities. Whether you’re a manufacturer or an enthusiast, understanding CNC technology is essential for leveraging its benefits in firearm production.

By following these guidelines, this content is optimized for search engines, making it more likely to rank well for the keyword “gun CNC.”